Call Us: +1 818 407 0523

Mail Us: bob@metaldyn.net

INDUSTRIAL SOLUTIONS FOR YOUR BUSINESS

About Us

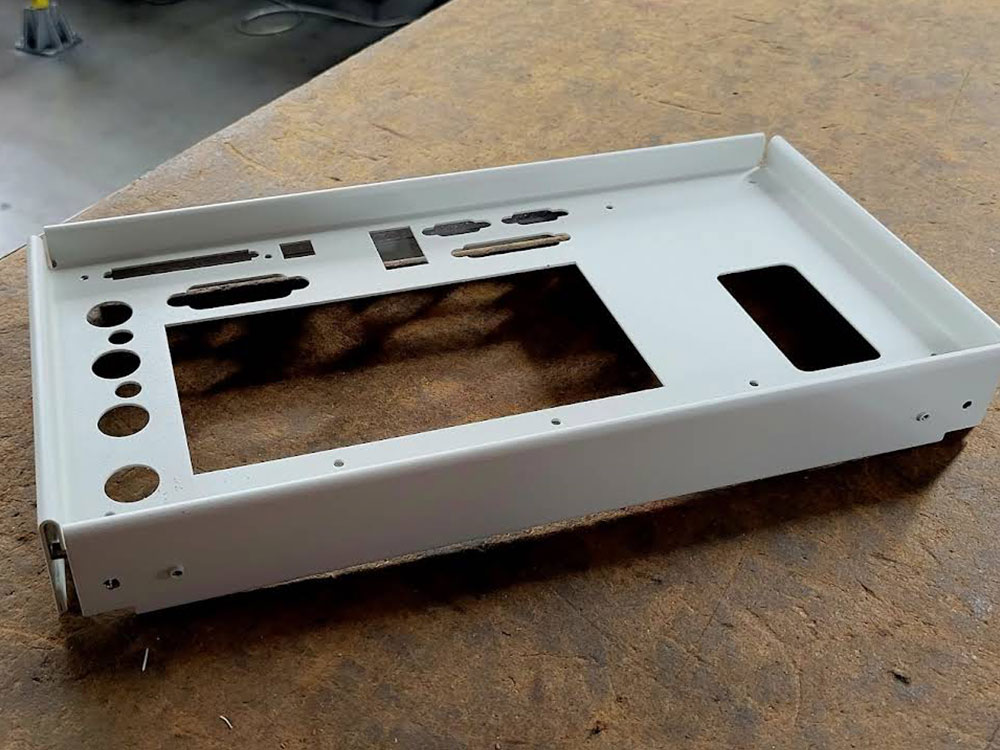

Metal Dynamics Precision is a Sheet Metal Working Company, it operates a top-notch Precision Metal working facility for the electronic, commercial, military and Aerospace Industries. We can punch, bend, Spotweld, plate and paint parts to your specifications.

What We Do

Our Services

Fabrication is the process of making something from raw materials. It typically involves the cutting, shaping, and assembling of materials to create a structure or object. Fabrication can involve techniques such as welding, machining, forming, and casting.

Cutting

Metal cutting is a process used to shape and form metal components by removing excess material in a precise manner. It can involve various techniques, such as sawing, grinding, and milling, and is used in a wide range of industries for various purposes. It is important to consider the type of metal that is being cut, as well as the desired shape and tolerances of the component, before deciding on the cutting process that will be used.

Forming

Metal forming is a process used to shape and form metal materials into desired shapes and sizes. It is typically done using high-pressure machines, such as presses, dies, and hammers. The process can be used on both ferrous and non-ferrous metals, and is often used to create products such as automotive parts, aircraft components, and other industrial products. The main processes used in metal forming include rolling, extrusion, forging, and stamping.

Metal Punching

This process is often used when creating complex shapes and designs in metal, and can be used to create holes, slots, and other features in the workpiece. Metal punching is one of the most common metalworking processes and is used in a wide variety of industries, from aerospace to automotive. Metal punching is a metalworking process that involves the use of a machine press to force a tool, called a punch, through the workpiece to create a hole.

Experience Quality Craftsmanship with Our Sheet Metal Fabrication Services

Sheet metal fabrication involves cutting, bending, and shaping sheet metal to create custom parts or products. At our facility, we use state-of-the-art equipment and advanced techniques to ensure the highest level of precision and quality in every project we undertake. From prototypes to large-scale production runs, we have the expertise and capacity to handle your sheet metal fabrication needs.

Sheet metal manufacturing involves the process of turning raw sheet metal into finished products. Our manufacturing capabilities include cutting, punching, forming, welding, and finishing. We work with a wide range of materials, including stainless steel, aluminum, and brass, and can create products in various shapes and sizes to meet your requirements.

Best Services For Your Business

Services Menu

| Service | Price | Duration | Category |

|---|---|---|---|

| Cutting | 200.00 | 0:15 | Fabrication Service |

| Forming | 300.00 | 0:15 | Fabrication Service |

| Metal Punching | 250.00 | 0:15 | Fabrication Service |

| Shearing | 200.00 | 0:15 | Fabrication Service |

| Stamping | 400.00 | 0:15 | Fabrication Service |

| Welding Service | 200.00 | 0:15 | Fabrication Service |

Book Your Appointment

Book Now

Get In Touch With Us

Contact Us

Email Us

Location

9640, Topanga Canyon PI,

STE H, Chatsworth, CA 91311